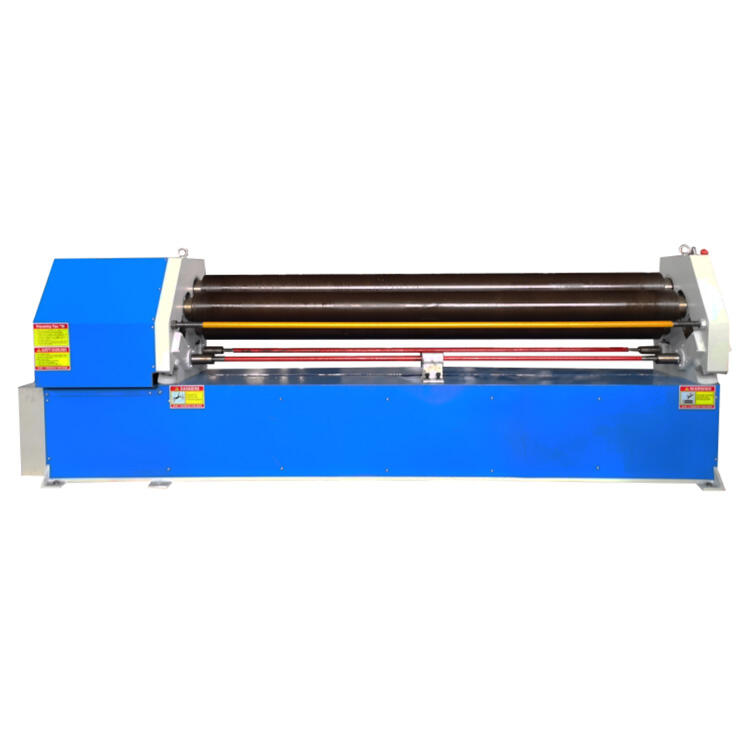

Understanding the Benefits of 4-Roll Plate Rolling Machines

When looking at the world of metallic fabrication, the kind of machinery as well as their accuracy directly reflects the quality of the consumable. One such crucial tool is the four-roll plate rolling machine which has become fast adopted as a result...

View More

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

TH

TH

FA

FA

MS

MS