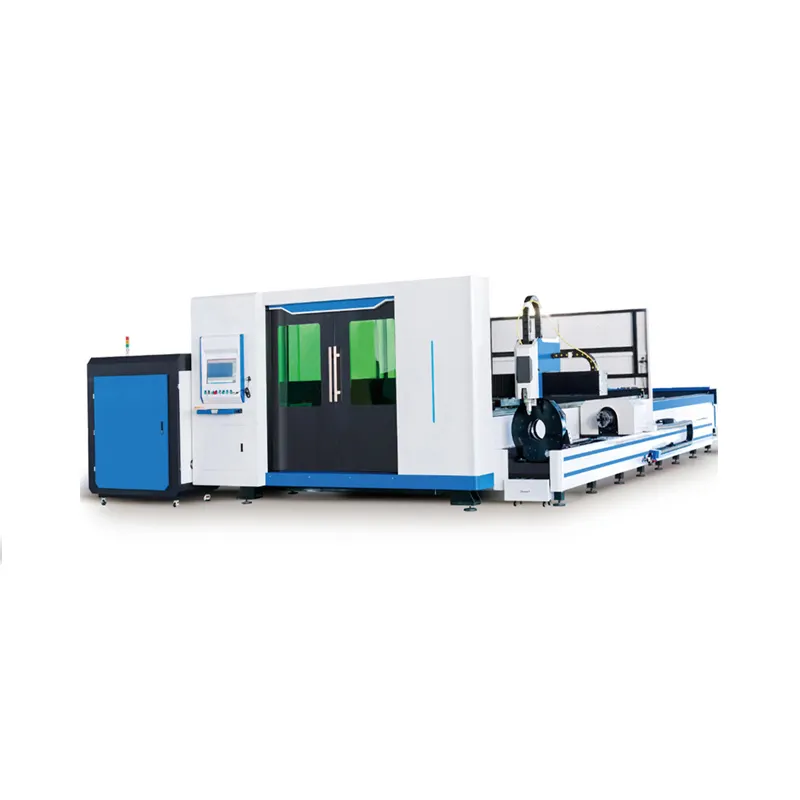

فهم فوائد آلات لف الصفائح المكونة من 4 لفات

عند النظر إلى عالم تصنيع المعادن، فإن نوع الآلات ودقتها تعكس بشكل مباشر جودة المواد الاستهلاكية. ومن بين هذه الأدوات الحاسمة آلة لف الألواح ذات الأربع بكرات والتي تم تبنيها بسرعة نتيجة...

عرض المزيد

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

TH

TH

FA

FA

MS

MS