الوصف

الأداء:

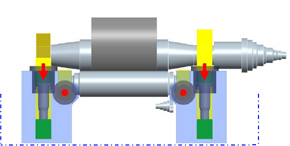

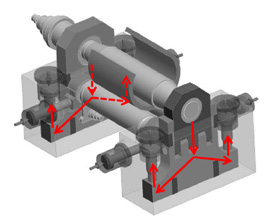

يمكن للأسطوانة العلوية التحرك عموديا؛

يتم تحقيق الانحناء المسبق من خلال الحركة الأفقية للأسطوانة السفلية، والتي تكون في وضع غير متماثل بالنسبة للأسطوانة العلوية؛

أثناء ثني اللوحة، يتم تشغيل ثلاث بكرات لتوفير عزم الدوران للألواح المتدحرجة؛

يظل ارتفاع الأسطوانة السفلية دون تغيير، مما يجعل التغذية والتشغيل أسهل؛

مجهزة بجهاز ضبط المواد الطولي.

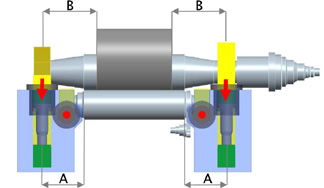

تتميز الماكينة ببنية متماثلة تمامًا، مما يتيح تحقيق أفضل تأثير انحناء وأعلى درجات الدقة.

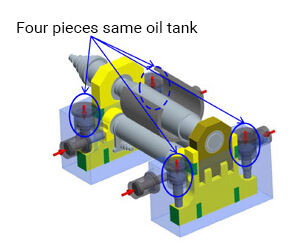

تعمل أربعة تجاويف متطابقة بدون قضبان بدقة مزامنة عالية

تعمل أربعة تجاويف متطابقة بدون قضبان بدقة مزامنة عالية

تصميم مضغوط مع أبعاد قاعدة صغيرة وبسيطة نسبيًا

تدفق طاقة قصير، أقصى صلابة

هيكل مغلق الإطار، استقرار الإطار العالي

|

الكود |

العنصر |

المواصفات |

|

|

1 |

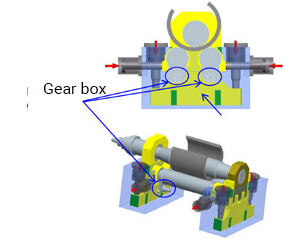

الهيكل |

ثلاث أدوات متغيرة للطلاء المركزي |

|

|

2 |

النموذج |

150 مم×3000 مم |

|

|

3 |

قطر العجلة العليا |

φ1060 مم |

|

|

4 |

قطر الدوار السفلي |

Φ920 مم |

|

|

5 |

مادة اللفائف |

42CrMo |

|

|

6 |

ثني المخروط |

إمالة الأسطوانة العلوية ±150 مم |

|

|

|

|

||

|

8 |

حدّة العائد |

345 ميجا باسكال |

|

|

9 |

ماكس سمك الانحناء |

150مم |

|

|

10 |

سمك ما قبل الانحناء |

130 مم |

|

|

11 |

سمك إعادة الثني |

130 مم |

|

|

12 |

الحد الأدنى لقطر الانحناء |

Φ6000 مم (سمك 150 مم) |

Φ5200 مم (سمك 130 ملم) |

|

13 |

حافة مسطحة زائدة |

≤ 2.5倍板 سميك |

|

|

14 |

الحد الأقصى لعرض اللوحة |

3000 مم |

|

|

15 |

رفع سرعة الأسطوانة العلوية |

سرعة العمل 60-120mm/min سرعة الحمل الفارغ 150-300mm/min |

|

|

16 |

دقة مزامنة الأسطوانة العلوية |

±0.2 مم |

|

|

17 |

سرعة الحركة الأفقية |

300-600 مم/دقيقة |

|

|

18 |

سرعة الانحناء |

0-4m/min |

|

|

19 |

ضغط العمل |

21 ميجا باسكال |

|

|

20 |

طاقة |

300 كيلوواط |

|

|

21 |

الأبعاد |

طول 9500 × 6840 × 5015 مم |

|

|

22 |

الوزن |

255000كيلو جرام |

|