Description

performance :

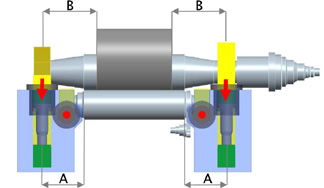

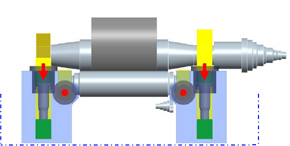

Le rouleau supérieur peut se déplacer verticalement ;

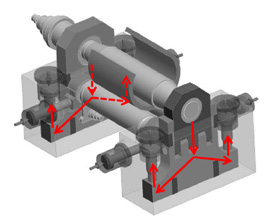

Le précintrage est obtenu grâce au mouvement horizontal du rouleau inférieur, qui se trouve dans une position asymétrique par rapport au rouleau supérieur ;

Lors du pliage des plaques, trois rouleaux sont entraînés pour fournir un couple de laminage pour le laminage des plaques ;

L'élévation du rouleau inférieur reste inchangée, ce qui facilite l'alimentation et le fonctionnement ;

Equipé d'un dispositif de réglage longitudinal du matériau.

La machine est dotée d'une structure entièrement symétrique. Le meilleur effet de pliage et la plus grande précision peuvent être obtenus.

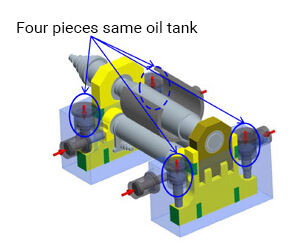

Quatre cavités identiques sans tige fonctionnent avec une précision de synchronisation élevée

Quatre cavités identiques sans tige fonctionnent avec une précision de synchronisation élevée

Conception compacte avec des dimensions de base relativement petites et simples

Courte puissance, rigidité maximale

Structure fermée du cadre, grande stabilité du cadre

|

code |

article |

spécification |

|

|

1 |

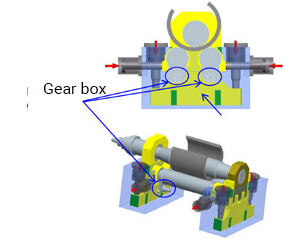

structure |

Machines à laminer à plaques de centre variable à trois rouleaux |

|

|

2 |

modèle |

150 mm × 3000 mm |

|

|

3 |

Diamètre du rouleau supérieur |

φ1060mm |

|

|

4 |

Diamètre du rouleau inférieur |

φ920mm |

|

|

5 |

Matériau des rouleaux |

42CrMo |

|

|

6 |

Cintrage de cône |

Inclinaison du rouleau supérieur ±150 mm |

|

|

|

|

||

|

8 |

Limite de rendement |

345 MPa |

|

|

9 |

Je suis désolé. Épaisseur de flexion |

150mm |

|

|

10 |

Épaisseur de pré-cintrage |

130mm |

|

|

11 |

Épaisseur de pliage |

130mm |

|

|

12 |

Diamètre de courbure minimal |

φ6000mm (épaisseur 150 mm) |

φ5200mm (épaisseur 130mm) |

|

13 |

Excédent de bord plat |

≤ 2,5 fois la taille du plateau |

|

|

14 |

Largeur max. de la plaque |

3000mm |

|

|

15 |

augmenter la vitesse du rouleau supérieur |

vitesse de travail 60 à 120 mm/min vitesse de charge vide 150 à 300 mm/min |

|

|

16 |

précision de synchronisation du rouleau supérieur |

±0,2 mm |

|

|

17 |

Vitesse de déplacement horizontal |

300-600 mm/min |

|

|

18 |

vitesse de pliage |

0 à 4 m/min |

|

|

19 |

Pression de travail |

21 MPa |

|

|

20 |

puissance |

300 kW |

|

|

21 |

Dimension |

L9500XB6840XH5015mm |

|

|

22 |

Poids |

255000 kg |

|