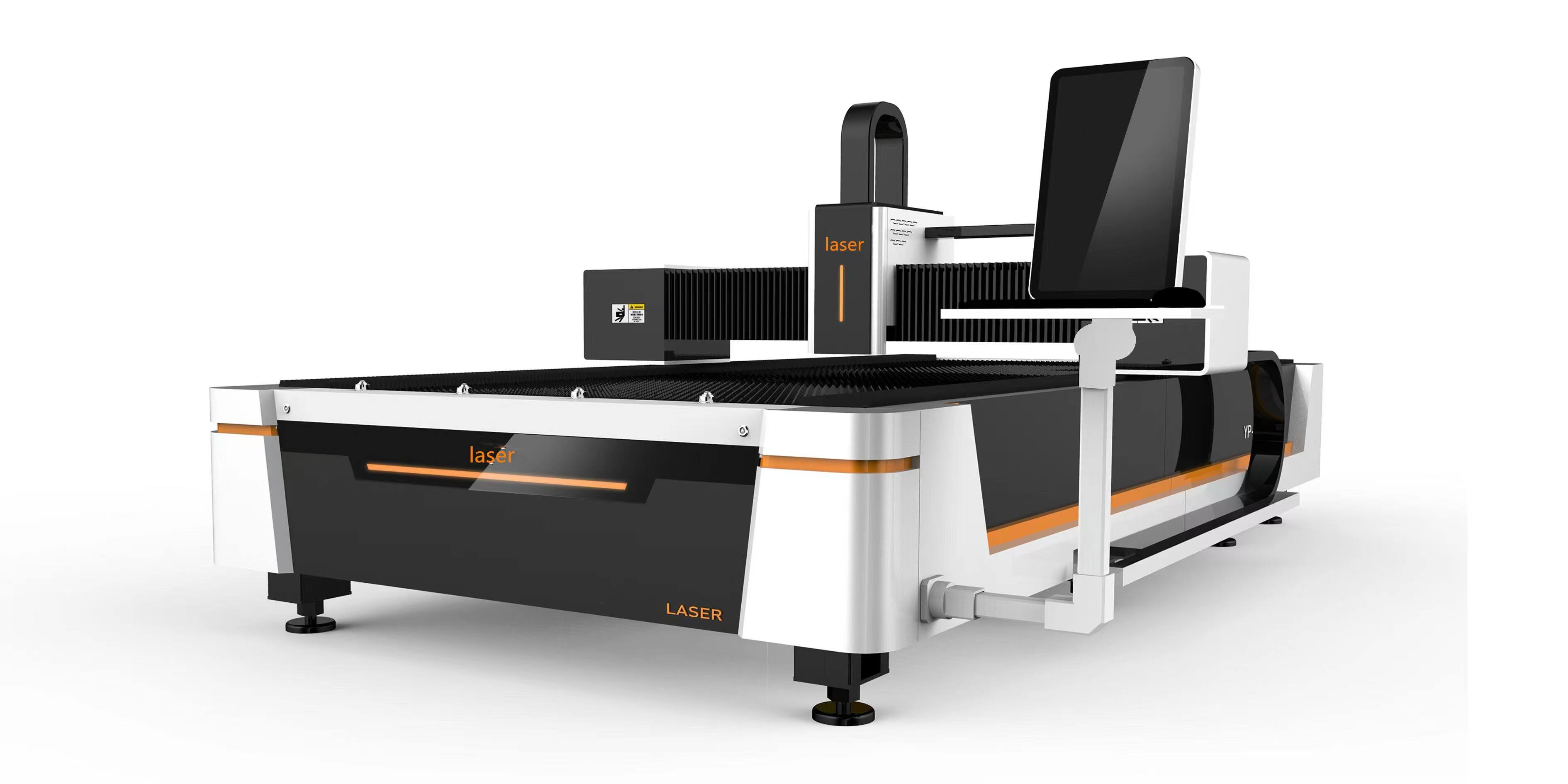

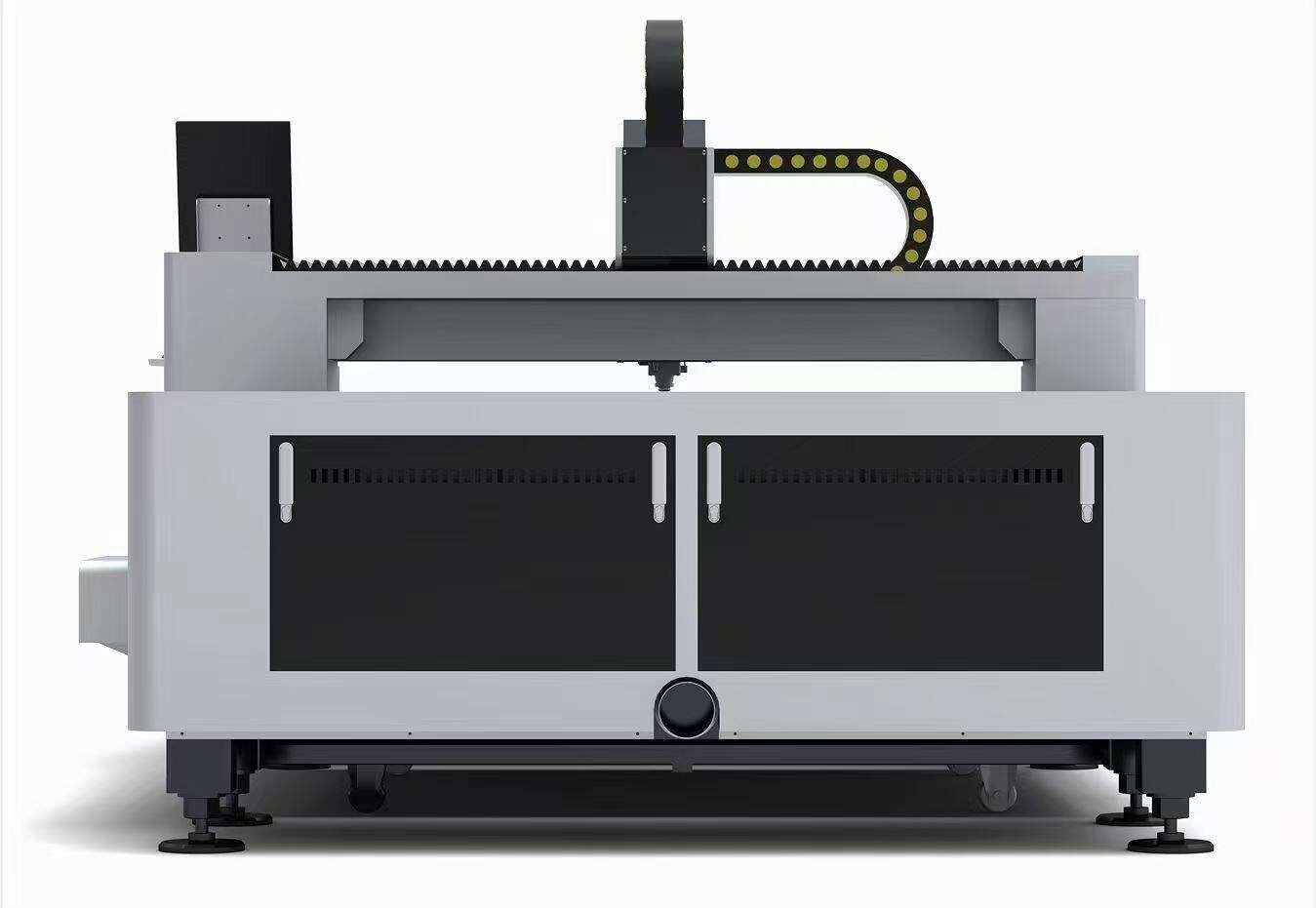

High Efficiency for Metal Cutting

When it comes to metal cutting, fiber laser cutting machines are among the most efficient tools available. The efficient melting and vaporization of metals occurs due to the high power density delivered to the surface of the metal enabling greater and faster cutting speeds. This feature makes them suitable for metal fabrication businesses like metalworking shops and automotive part production, where extensive metal cutting is commonplace.