Понимание преимуществ 4-валковых листопрокатных машин

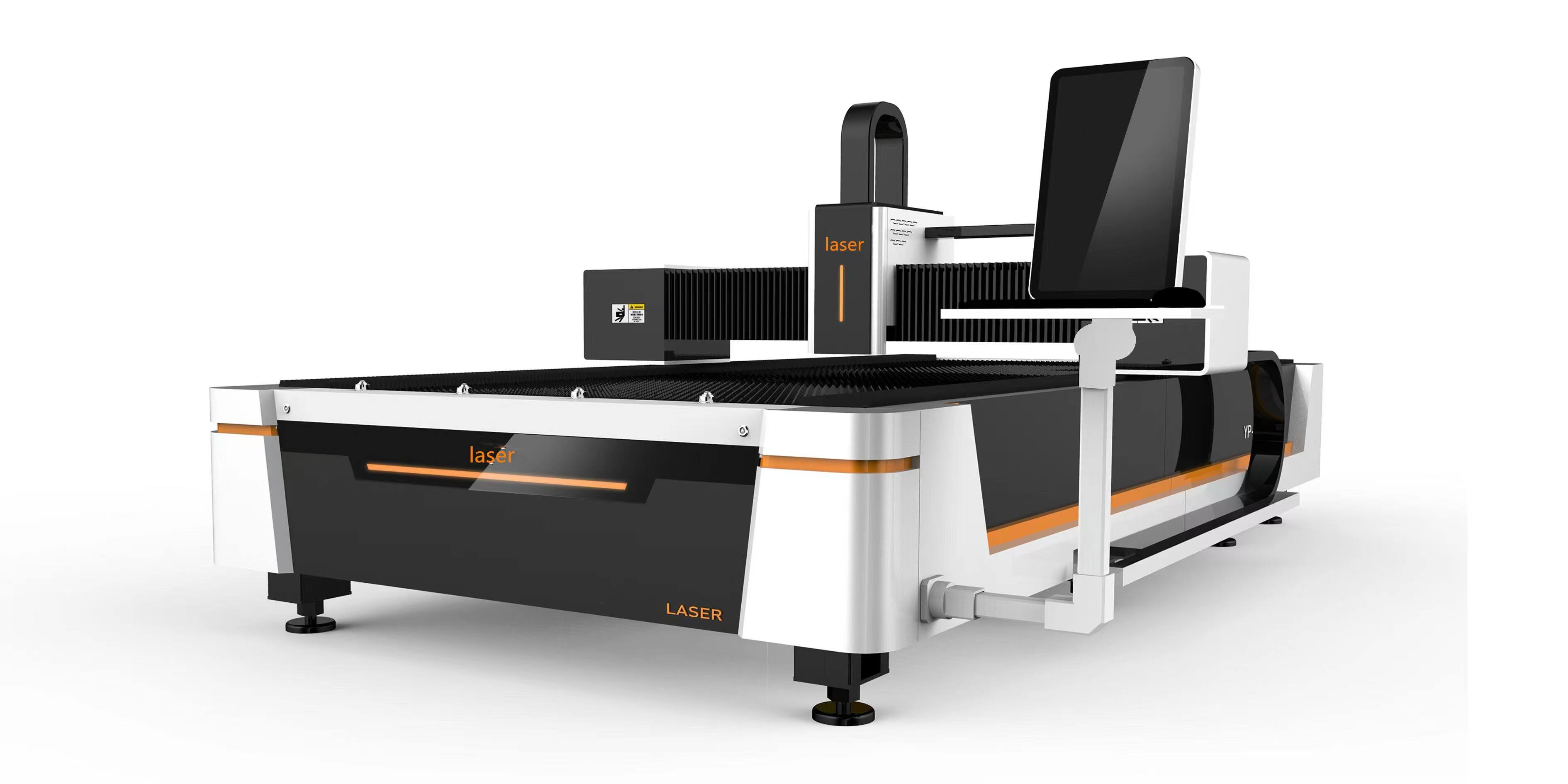

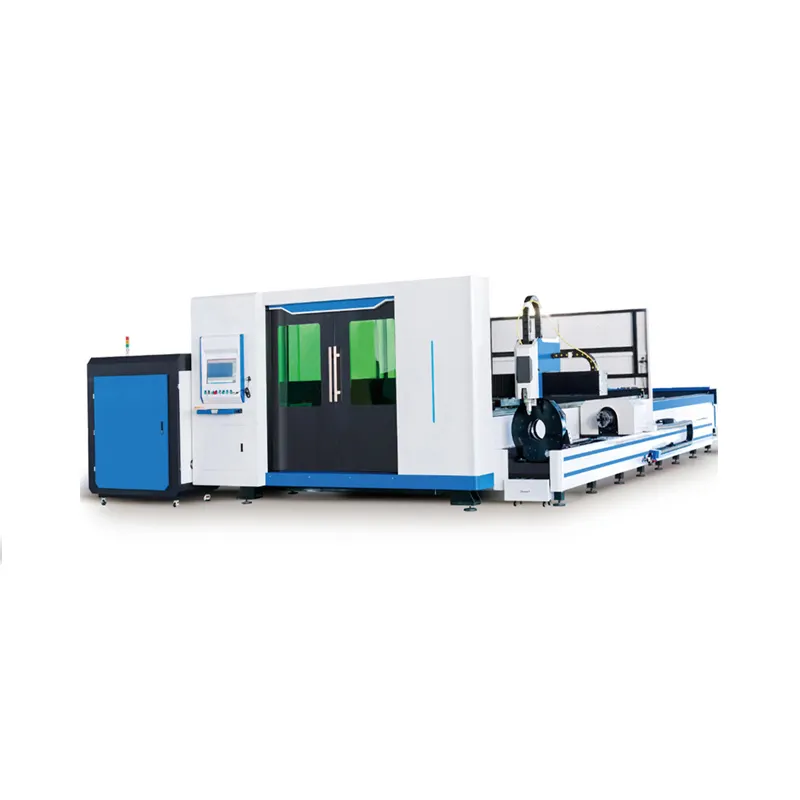

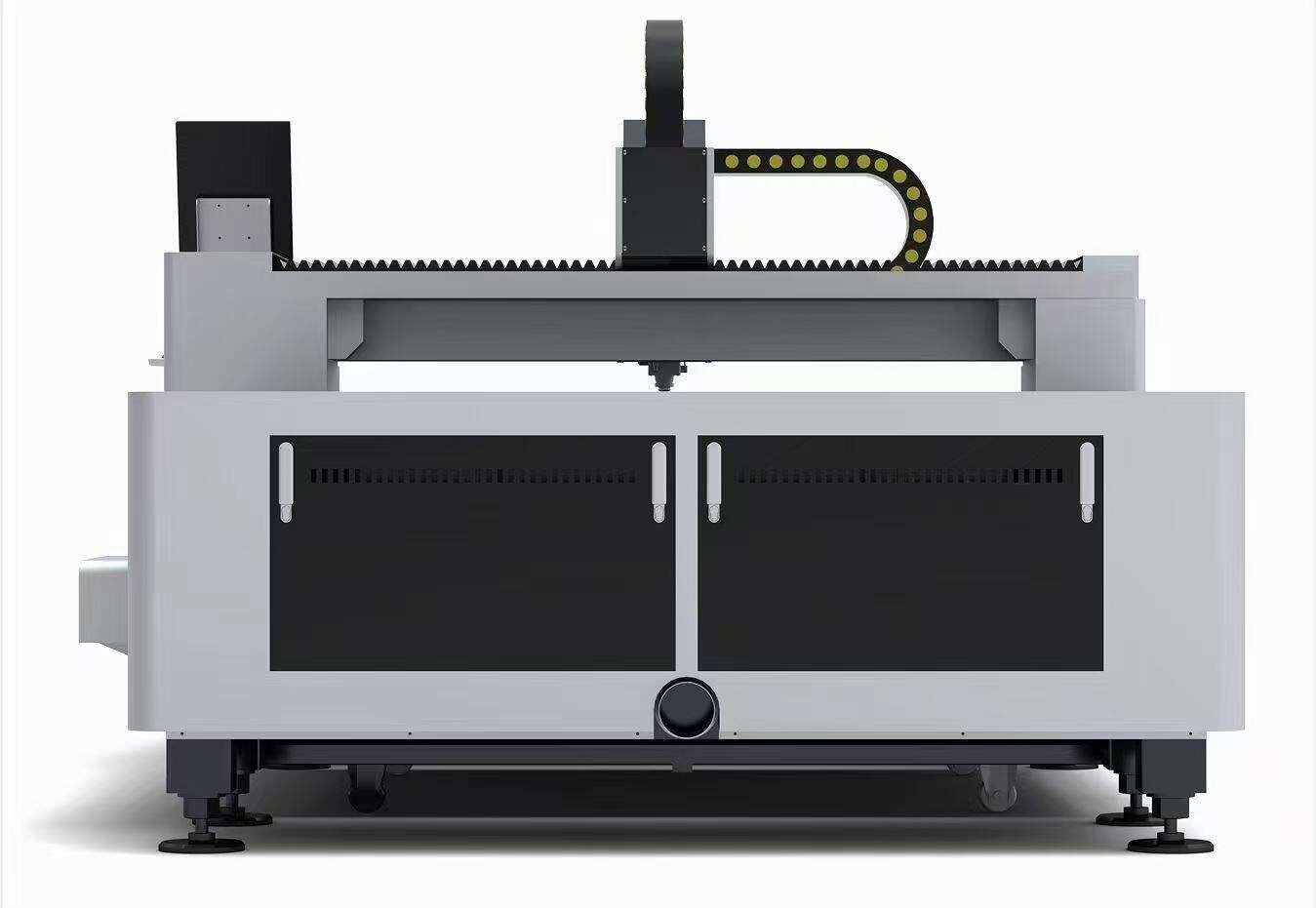

Когда речь идет о мире металлической обработки, тип машин, а также их точность напрямую отражают качество расходных материалов. Одним из таких важных инструментов является четырехвалковая листогибочная машина, которая быстро была принята в результате…

СМОТРЕТЬ БОЛЬШЕ

EN

EN

AR

AR

CS

CS

FR

FR

DE

DE

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

TH

TH

FA

FA

MS

MS