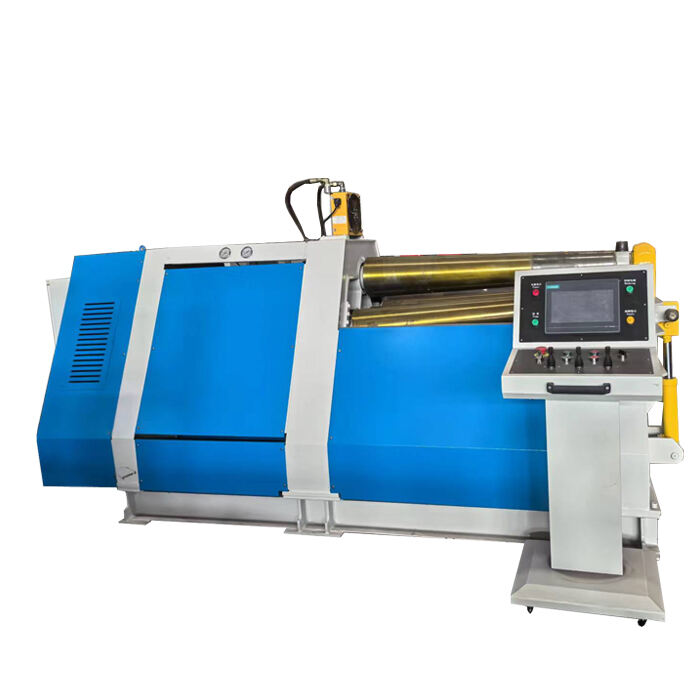

W12 hydraulics plate rolling machine with 4 rolls W12C-12x2000

Special hydraulic diagonal down adjust cone plate rolling machine with 4 rolls has the functions of pre-bending and coning at the same time. Its structure mainly consists of base, drop end side rack, fixed side rack, working roller, driving device, lower (side) roller lifting device, drop end device, hydraulic system, electric control system and other components.

Description

Hydraulic Cone Plate Rolling Machine with 4 Rolls

1、Introduction of the Main Body

Special hydraulic diagonal down adjust cone plate rolling machine with 4 rolls has the functions of pre-bending and coning at the same time. Its structure mainly consists of base, drop end side rack, fixed side rack, working roller, driving device, lower (side) roller lifting device, drop end device, hydraulic system, electric control system and other components.

The machine is compact in structure, reliable in use and easy to maintain. Digital display device is installed for moving the lower roller up and down and lifting the side roller. Therefore, the operation is convenient and the control is accurate. The overturn and reset of the drop end side of the up roller and the balance of the up roller are performed by the screw, so that the discharge is more convenient.

Four rollers of this machine are driving rollers. The up roller is in the fixed position, while the lower roller can lift up and down. When the metal sheet is pinched by up and lower rollers and they start a relative rotation, friction happens between sheet metal and the working rollers, leading to the movement of sheet metal. The rise and fall of side roller can make the plate bend. Adjusting the movement of the side roller can achieve the required arc or radius of curvature of the circular work-piece.

At one end of the drop end side rack of the machine, a coning device is arranged on the inner wall of the drop end side rack, which functions is to overcome the axial force in the cone bending process of the sector plate. An overturning oil cylinder is arranged on the outside. When the rolling work is finished, the balance oil cylinder acts and the overturning oil cylinder acts to make the drop end side rack overturn. After the work-piece is removed, the overturning oil cylinder acts to restore the drop end side rack, and this working cycle ends.

The bearing seat of the lower roller and the side roller are provided with tilting hinges, which can cooperate with the tilting upward extension of the roller shaft when the cone is rolled. When the customer requires to roll cones, the lower roller and the side roller incline to rise, and cooperate with the cone device of the drop end side to complete the rolling action. When the customer requires to roll the standard cylinder, it is only necessary to level the lower roller and the side roller.

2、Main Technical Parameter

|

Model |

W12C-6x1500 |

|

Max. bending width |

1500mm |

|

The length of working roller |

1550mm |

|

Max. bending thickness(σs≤245MPa) |

6mm |

|

Max. bending thickness(σs≤245MPa) |

5mm |

|

Range of rolling cones |

≤120° |

|

Range of rolling small head diameter |

≥120mm |

|

Diameter of top rollers |

Small headφ90 mm |

|

Big head φ260 mm |

|

|

Diameter of bottom roller |

Small headφ85 mm |

|

Big head φ255 mm |

|

|

Diameter of side roller |

Small headφ85 mm |

|

Big head φ255 mm |

|

|

Driving type |

four rollers drive |

|

Rolling speed |

About 3(m/min) |

|

Motor power |

5.5kW |

3、Structure of the Main Body

The main structure of the equipment is composed of up roller device, lower roller device, side roller device, drop end device, left and right side rack, transmission device, chassis and balance device, hydraulic system, electronic control system, etc.

3-1、Up roller device

The up roller device is composed of up roller bearing seat, up roller, double-row self-aligning bearing, etc.

Double row self-aligning bearing adopts low speed and heavy load self-aligning roller bearing.

The upper roller is made of alloy steel 42CrMo, which is treated by tempering HB260~300 after rough machining. Grade II flaw detection of GB/T6402-1991 is conducted, in accordance with the JB/ZG4289-86 roll steel standard, and the stiffness is in line with (1/700~1/1000)L (L -- refers to the distance between the center line of the two sides of the rack)

3-2、Lower roller device

The lower roller device is composed of lower roller bearing seat, oil cylinder of lower roller ,lower roller, double-row aligning bearing, etc.

Oil cylinder of the lower roller r provides clamping force during rolling and friction for rolling.

Double row self-aligning bearing adopts low speed and heavy load self-aligning roller bearing.

The lower roller is made of alloy steel 42CrMo, which is treated by tempering HB260~300 after rough machining. Grade II flaw detection of GB/T6402-1991 is conducted, in accordance with the JB/ZG4289-86 roll steel standards, and the stiffness is in line with (1/700~1/1000)L (L -- refers to the distance between the center lines of the two sides of the rack).

The lower roller lifting cylinder is made of 45# forgings with heat treatment and tempering HB217~255.

3-3、Drop end device

The drop end device consists of an overturning seat, an overturning cylinder, etc. Overturning cylinder piston rod chromium plating treatment. The overturning of the drop end device facilitates the removal of the product along the roller axis.

3-4、Fixed side rack, drop end side rack and chassis

The heavy-duty and high-reliable welded rack construction is mounted on the solid bottom integral frame structure to ensure accuracy and reliability of the machine tool. The racks and chassis are welded parts of Q235B steel plate, which are tempered after welding. The two cylinders of the lower roller work with a rodless cavity to maintain the consistency of the system, that is, the working pressure is consistent, the matching is consistent, and the effective area of the cylinder is large. There is only one dynamic seal. The lifting speed is suitable for the rolling plate process requirements, which is easy to control the synchronization of the two cylinders, easy to maintain. And the maintainability is greatly strengthened.

The bottom overall frame structure is made of shaping plate welded as a whole and processed after vibration de-stress. The frame structure has high coefficient of torsional section, good strength and rigidity, convenient installation and easy use, especially meets the operating requirements with strong mobility, low requirements for the foundation, and it’s also easy to move.

3-5、Transmission device

The device has a motor to drive the distribution box, which then drives a roller shaft with a coupling.

3-6、Hydraulic system

- General overview

Hydraulic system production is strictly implemented in accordance with the national standard and line standard. Layout is reasonable. It also takes high efficiency, energy saving, reduction of waste and heat source into full consideration. The system is independent and the connection point adopts professional sealant to prevent leakage. It’s easy and convenient to repair and maintain. The hydraulic pump adopts high pressure oil pump, and the hydraulic valve adopts Yuken superposition valve series, and the test pressure is 25MPa without leakage. The layout of pipeline is simple with less leakage, easy maintenance and convenient debugging. In order to ensure oil clean, an oil filter is arranged at the oil pump port. The pressure oil from the oil pump first enters the pressure regulating system, adjusts the pressure, and then passes through the valve block and leads to the cylinder through the reversing valve.

- Components of hydraulic system

The hydraulic system is composed of oil pump, valve group, fluid connector, hydraulic auxiliary parts, etc.

Hydraulic valve selects superposition valve series, which has simple pipeline layout, easy maintenance and debugging.

The system is composed of three circuits, over-pressure protection and pressure regulation circuit, synchronous circuit and speed circuit. The pressure regulating circuit adjusts the working pressure of the system through the main relief valve. The working pressure of the system is 19.5MPa.

Synchronization circuit synchronously shunt the rise and fall of the lower roller and side roller through the shunt throttle valve , throttle valve can adjust up and down. Displacement sensor detects so that synchronization accuracy of the lower roller and side roller will be maintained within ±0.05mm.

Speed circuit controls the overturn and reset of drop end side, and adjusts the throttling speed of the circuit through the throttle valve.

- All kinds of protection

The rise and fall of the lower roller and side roller are respectively provided with relief valve for pressure limit protection.

3-7、Electric control system

- General Overview

The electronic control system is composed of electronic control cabinet and operation console. The control apparatus of this machine (including PLC) are installed in the power distribution cabinet. Screen data display makes operation easy. The main circuit uses three-phase 380V/50Hz alternating current, the NC control input circuit uses 24V direct current, the control output circuit uses 220V/50Hz alternating current. The main motor drives the hydraulic pump station to provide power. The main components are made of domestic famous products that are made in strict accordance with national standards, the layout structure is reasonable with necessary safety protection measures.

The control cabinet is equipped with all the control buttons, indicator lights and programmable touch display which are needed in the process of product rolling, so as to monitor and control the rolling working state of the whole machine.

- All kinds of protection

The motor has the corresponding circuit breaker for over-current short-circuit protection and the corresponding thermal relay for overload protection;

The rise and fall of the lower and side roller have corresponding limit switches for limit protection;

The overturning and resetting of the overturning cylinder are respectively provided with the upper and lower limit switch protection;

The main power circuit breaker has shunt tripper, and there is an "Emergency Stop" button at the operating table and the side of the drop end to cut off the main power remotely.

- All kinds of interlock

After the drop end rack is fully reset, lifting of the lower roller and side roller , the positive and negative rotation of the up and lower side roller and other actions can be carried out (with the limit switch of "drop end rack reset" for detection);

- Fault indication

When the main motor is overloaded, the fault indicator light will prompt. When the PLC fails, the failure indicator light prompts.

- Function of digital display

The digital display system has the functions of real-time monitoring, data transmission and power failure memory in the process of rolling. The human-machine interface is displayed intuitively and clearly in Chinese.

- Real-time monitoring function

The monitor screen displays the up-down displacement(Yg、Yf) of lower roller cylinder and lifting volume(X) of the side roller.

- Human-machine communication function

Through the system operation inputs and LCD displays, you can realize the editing, modification and other functions of the parameters for work-piece. Industrial controller PLC can control and ensure the accuracy of synchronization according to the automatic detection of the position of both ends of the up roller. The displacement resolution of the displacement sensor is 0.05mm. It has the function of automatic fault diagnosis.

4、Description of Equipment Operation Performance

The four rollers output firstly through the motor, and then through the distribution box, they are respectively connected with the up roller, lower roller and side roller by the coupling to transfer the driving torque, in order to provide bending deformation torque for the work-piece and ensure the accurate and stable operation of the rolled work-piece.

The rise and fall of the lower roller is driven by oil cylinder. Drive the lower roller up and down vertically to keep the clamping end of the work-piece prebent and clamped.

Side roller obliquely lifts with reciprocating movement by the cylinder. The reciprocating position of the side roller determines the curvature of the work-piece. Both sides of the side rollers can be adjusted separately in the process of cone and cylinder processing.

5、Main Standard Component Configuration

- Double row self-aligning bearing ZWZ, China

- Main hydraulic valve Yuken, China

- Hydraulic pump HCHC, China

- Hydraulic motor Mengniu, China

- PLC programmable controller XINJE, China

- Main electrical components Siemens, Germany

- Sealing ring AILATE(Sino-german joint venture)