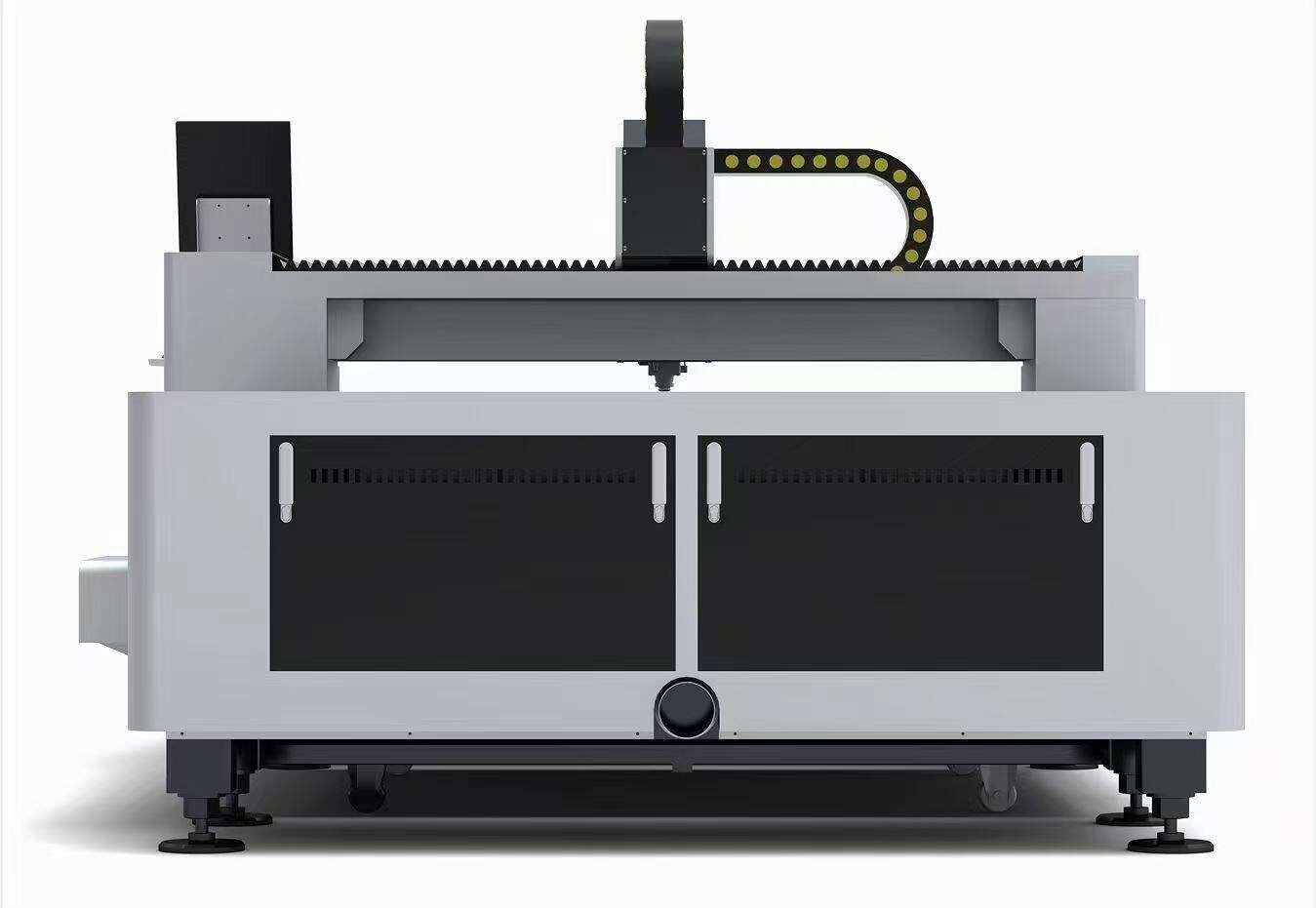

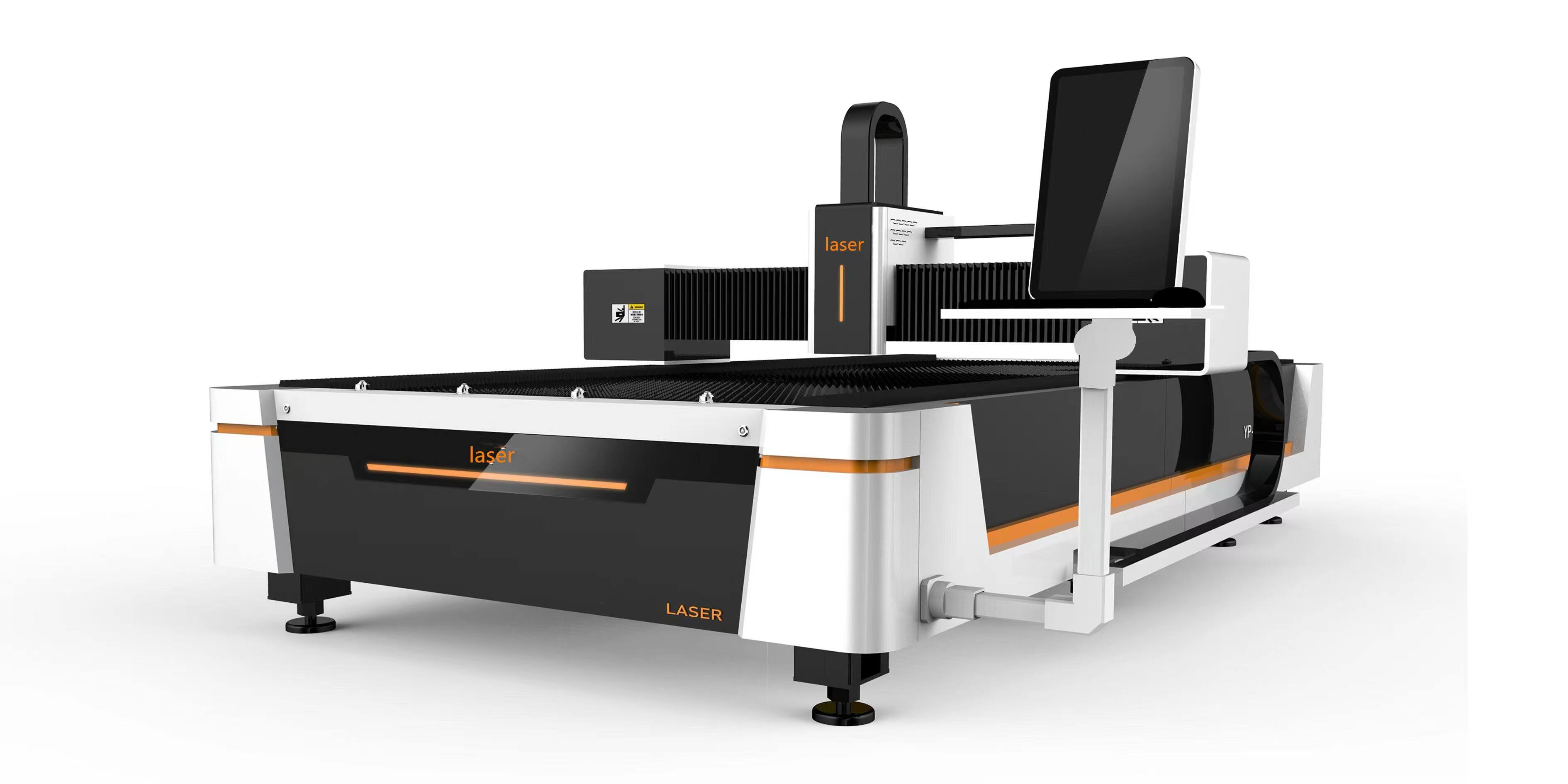

Laser cutting is more efficient than the conventional methods. Laser cutting not only facilitates high speed cutting but also narrow kerf cutting which helps save on materials and time. Other methods like sawing and shearing are comparatively slower with a bigger cutting width. While laser cutting allows for complex shapes to be cut in one go, melee methods would require multiple operations to achieve the same ease