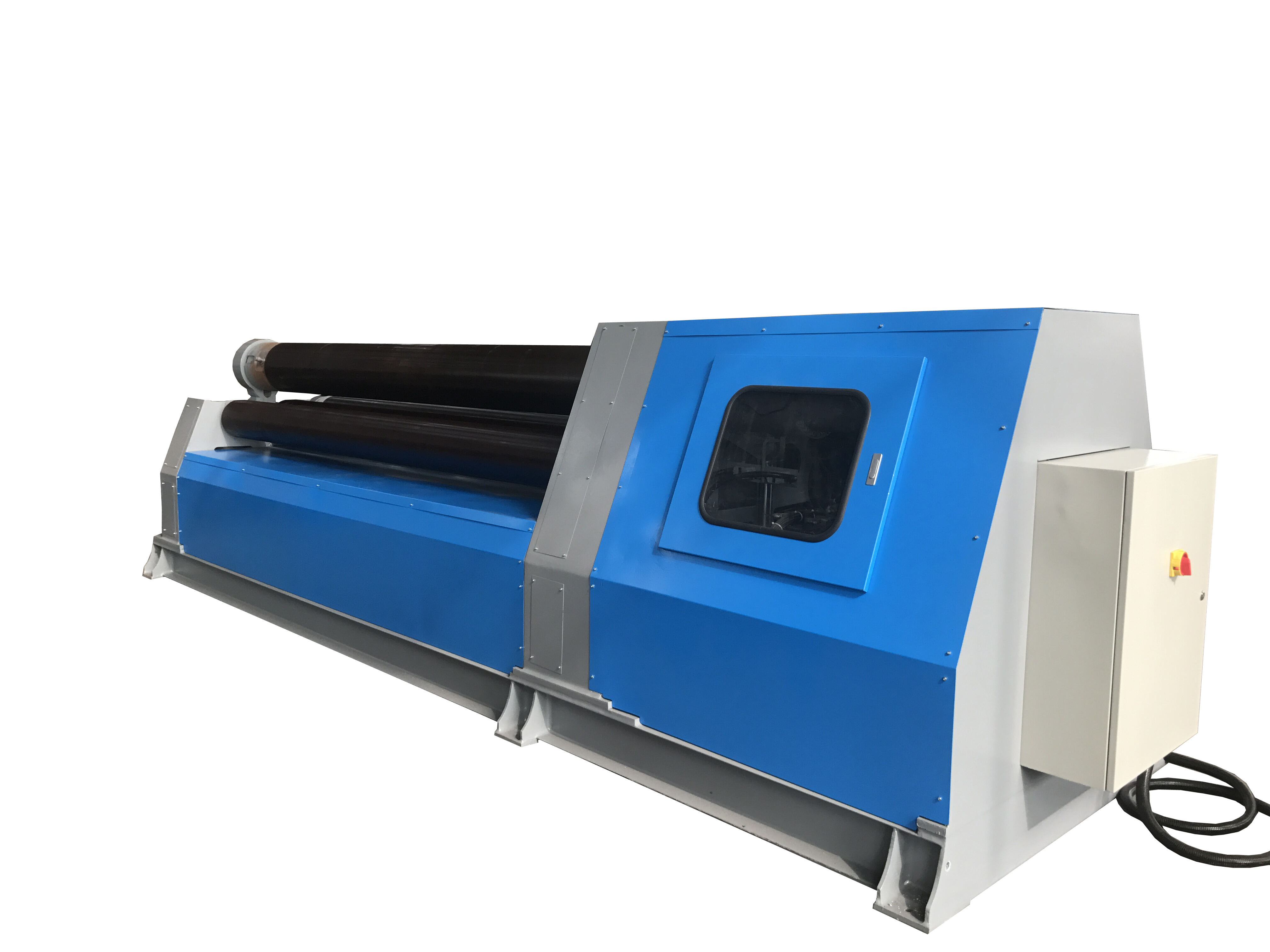

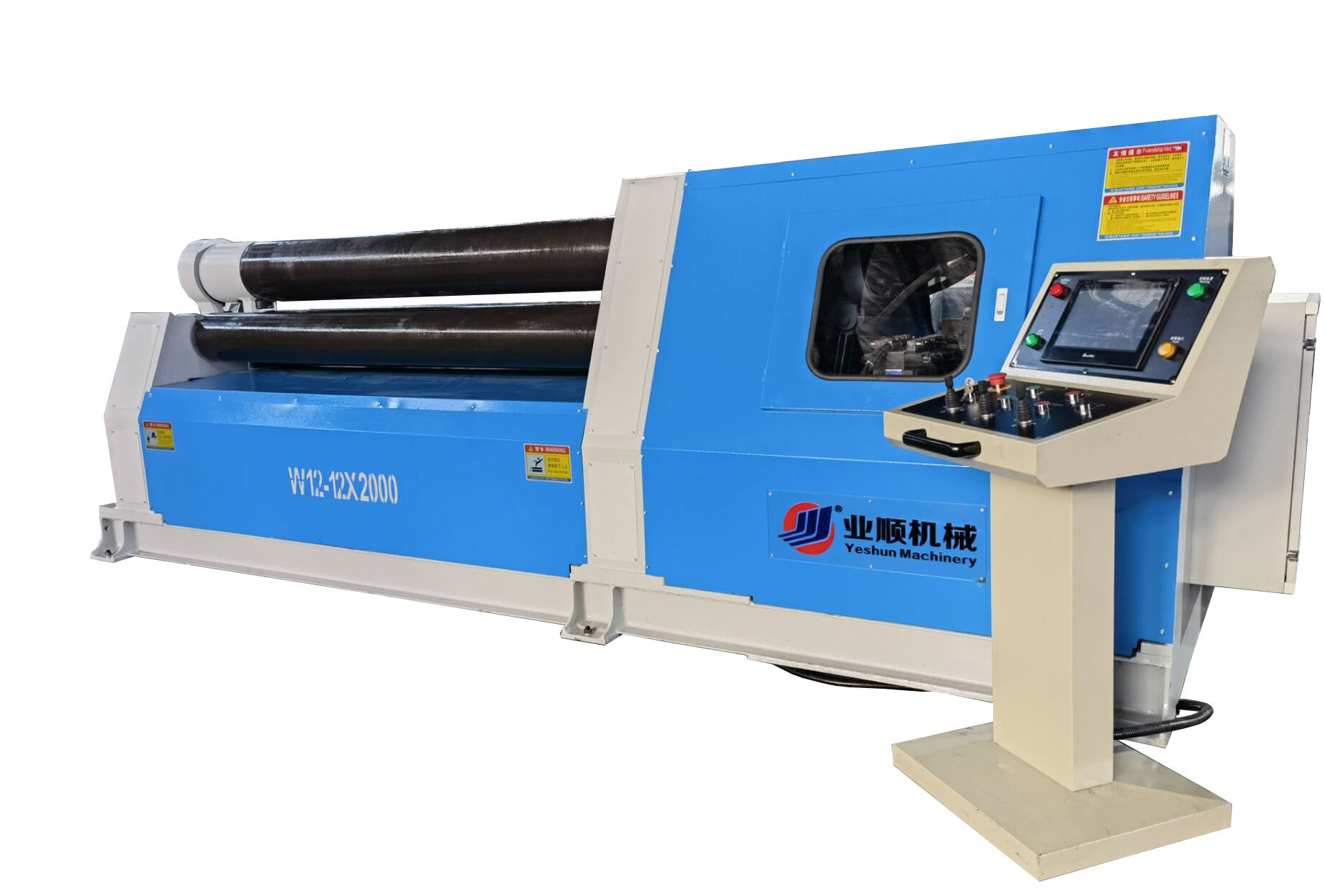

Comprehensive Testing and Inspection

In the end, all our plate rolling machines fabricated within the factory undergo several rounds of inspection and testing. They include functional tests, precision measures, and performance checks for complete integration of the machine. The machines that qualify under the quality detesting character will be available for customers ensuring that it is top grade equipment.