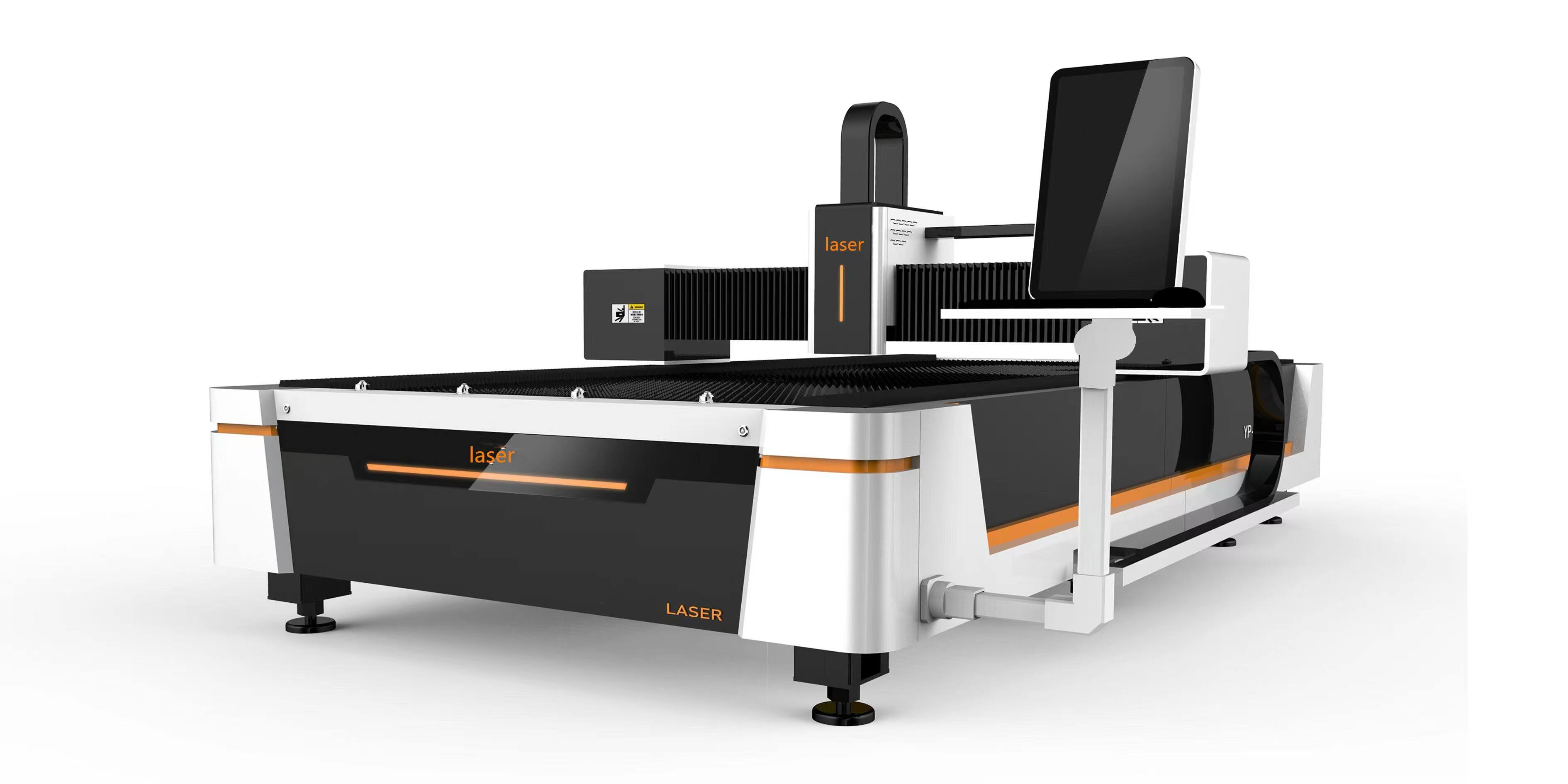

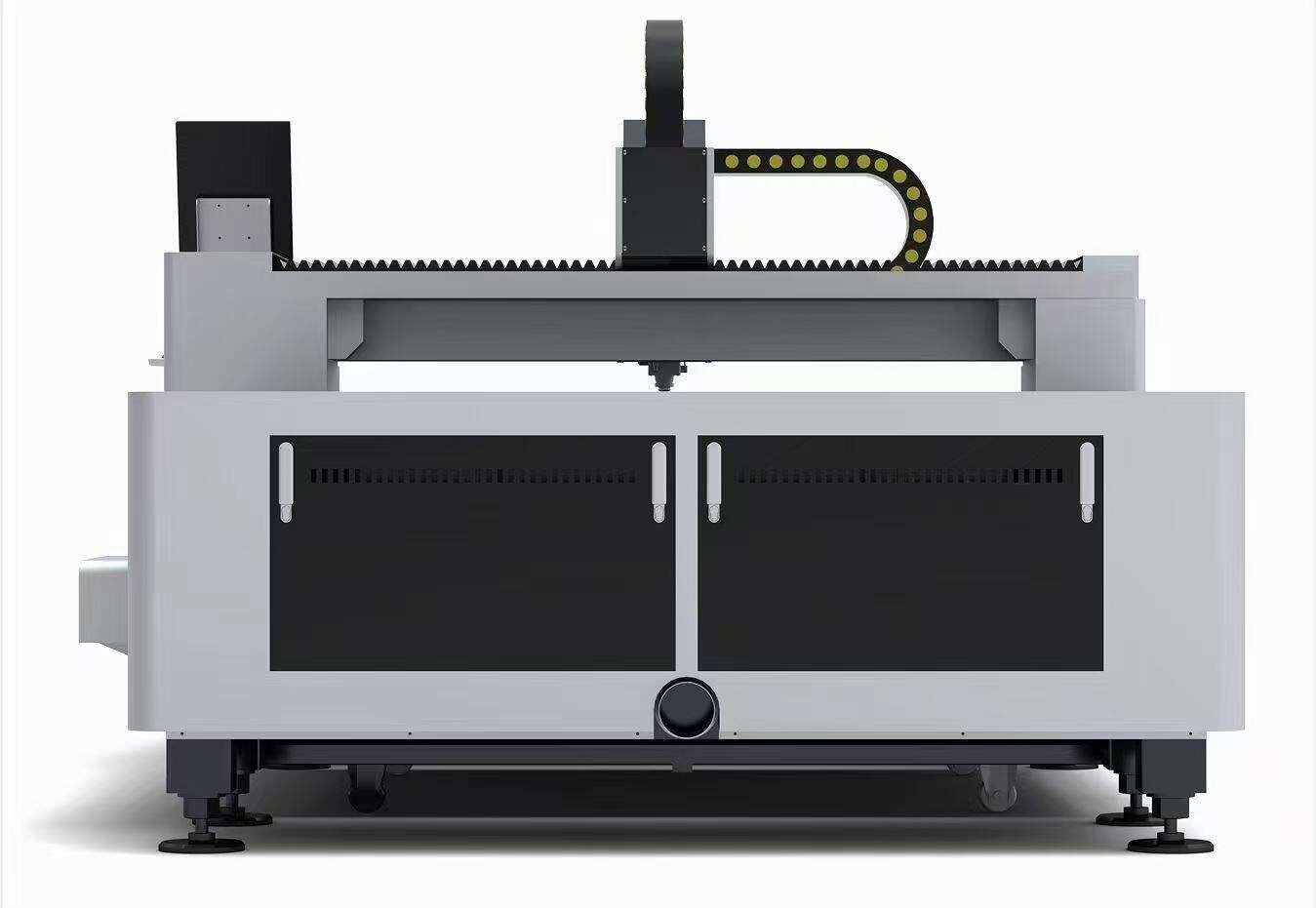

High - Precision Cuts

Achieving an intricate and detailed cut, laser cutting can accomplish tasks with overwhelming precision, often getting within fractions of a millimeter. This is especially valuable for industries like electronics manufacturing that require precision components to be cut with extreme accuracy. Other methods lasercutting out perform include mechanical cutting with saws or punches as they introduce greater errors caused by vibration, tool wear, and other imprecise factors.