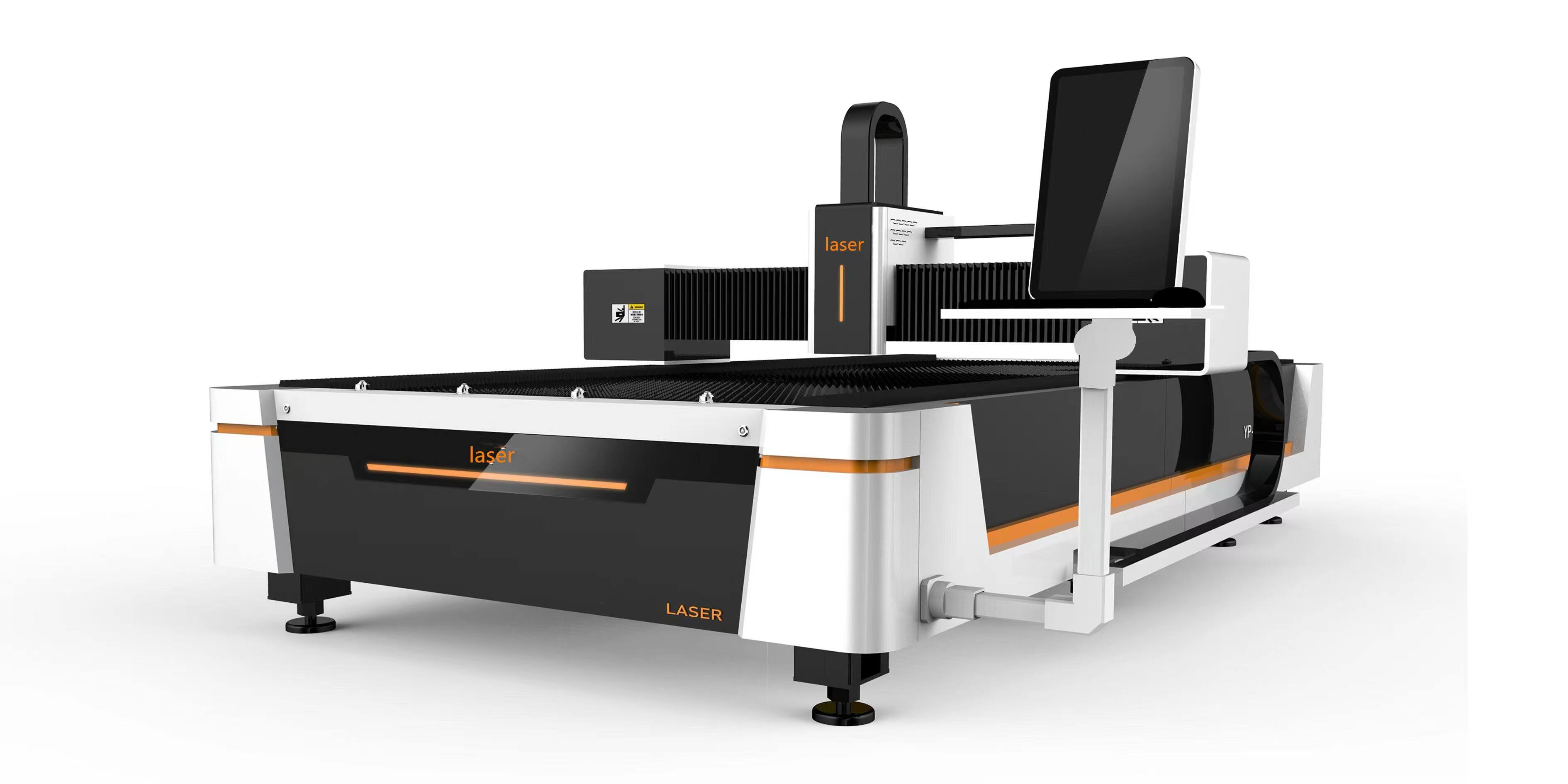

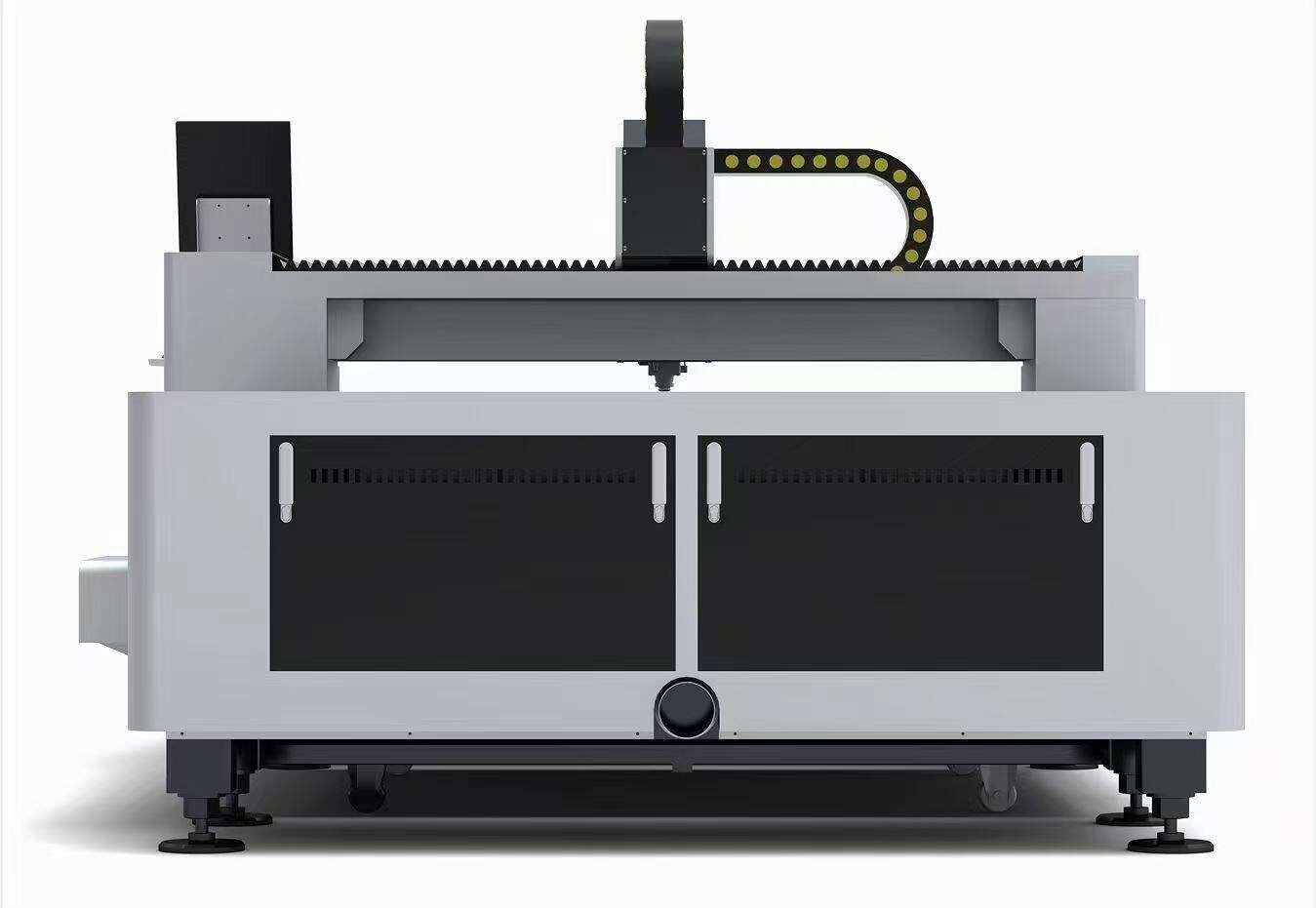

Electronics Manufacturing

CNC laser cutting is used to cut metal enclosures, circuit boards and precision parts for electronics manufacturing. In order to produce complex and small electronic components with high reliability, sharp and precise cuts alongside intricate details need to be produced.