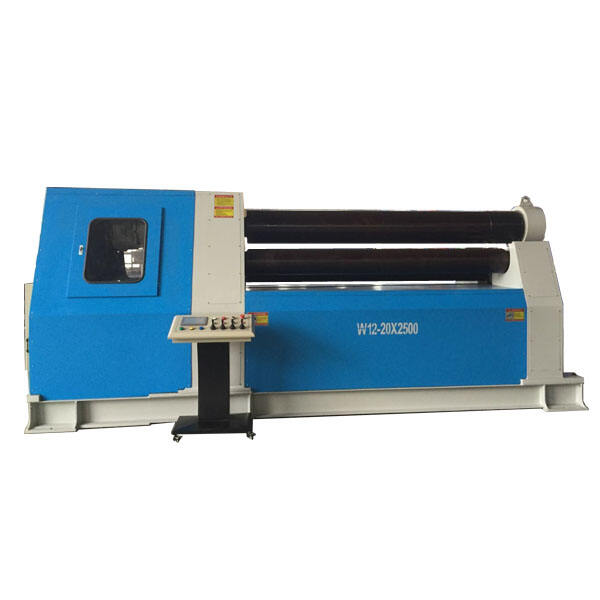

Suitable for Large - scale Industrial Applications

The wider bending range makes these machines suitable for heavy duty industrial applications such as large construction, machinery manufacturing, and shipbuilding. These types of industries rely on precise cylindrical bending of large sized curved plates to form the complex structures that are required for these large scale engineering projects.