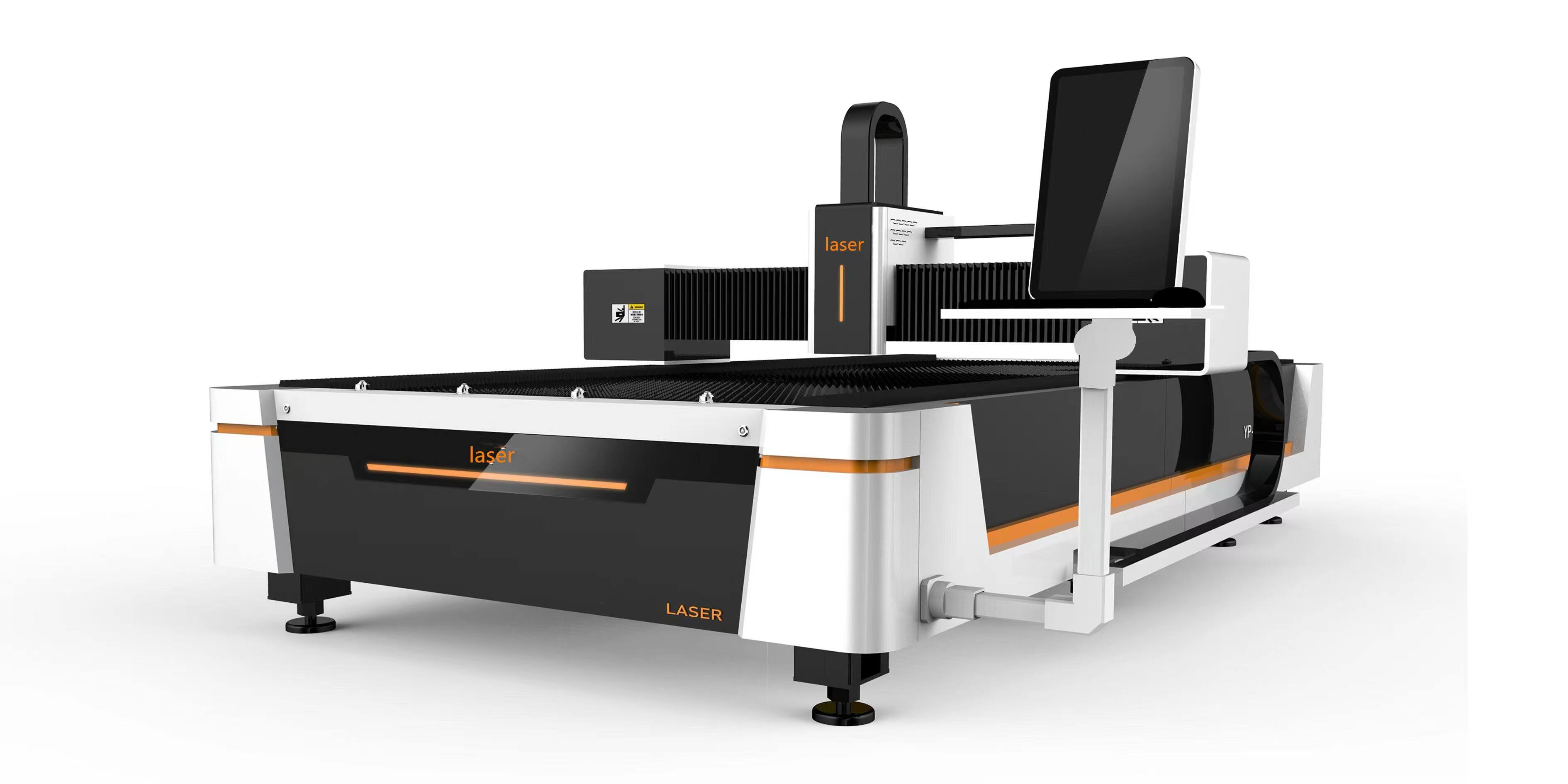

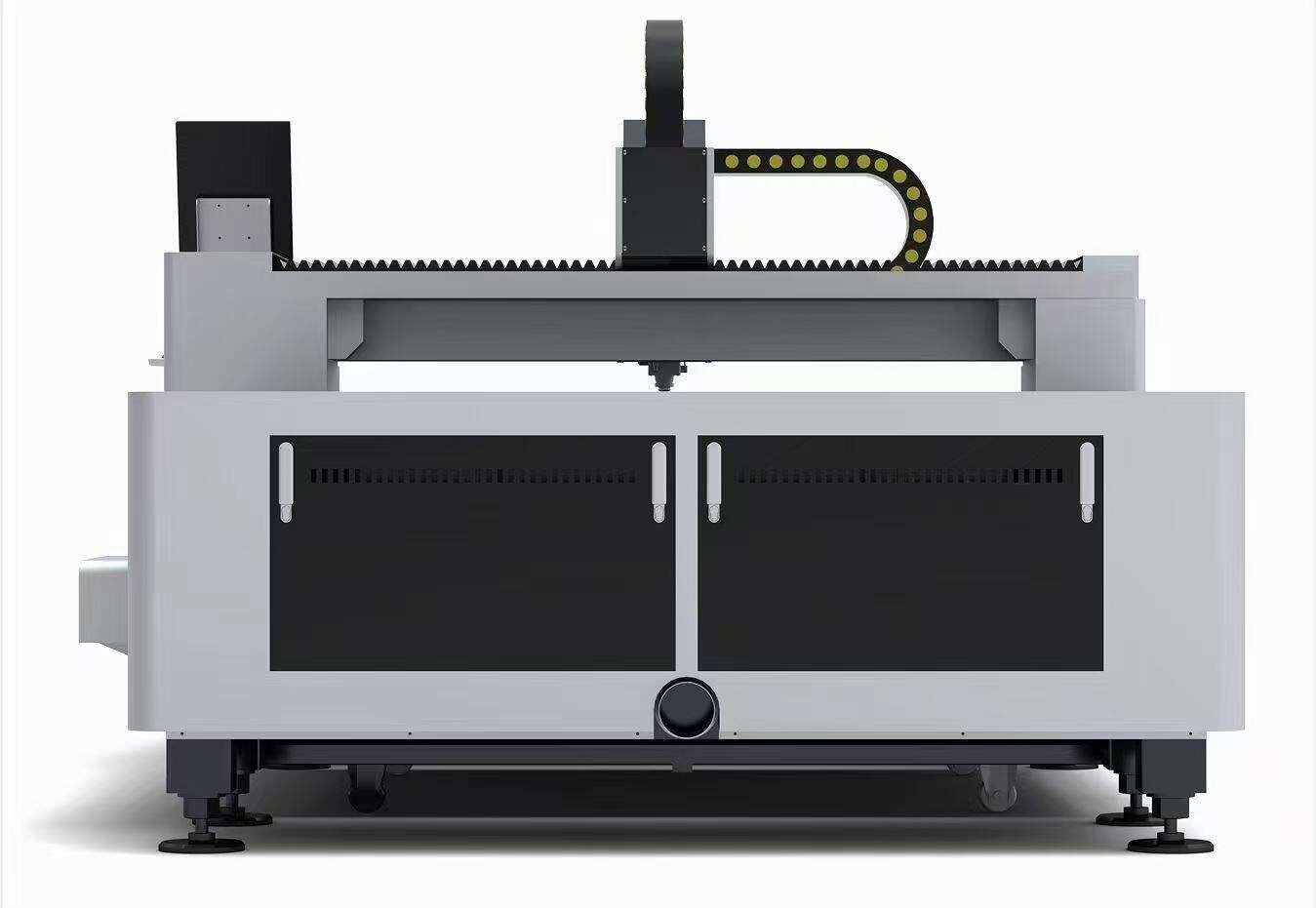

Suitable for a Wider Range of Materials

Plasma cutters usually concern themselves with metallic objects, however, laser cutting seems to do better with both versatility and the ability to cut wood, ceramics, and plastic. Additonally, laser cutting is the superior choice with various materials not as easily adjustable by plasma cutters.