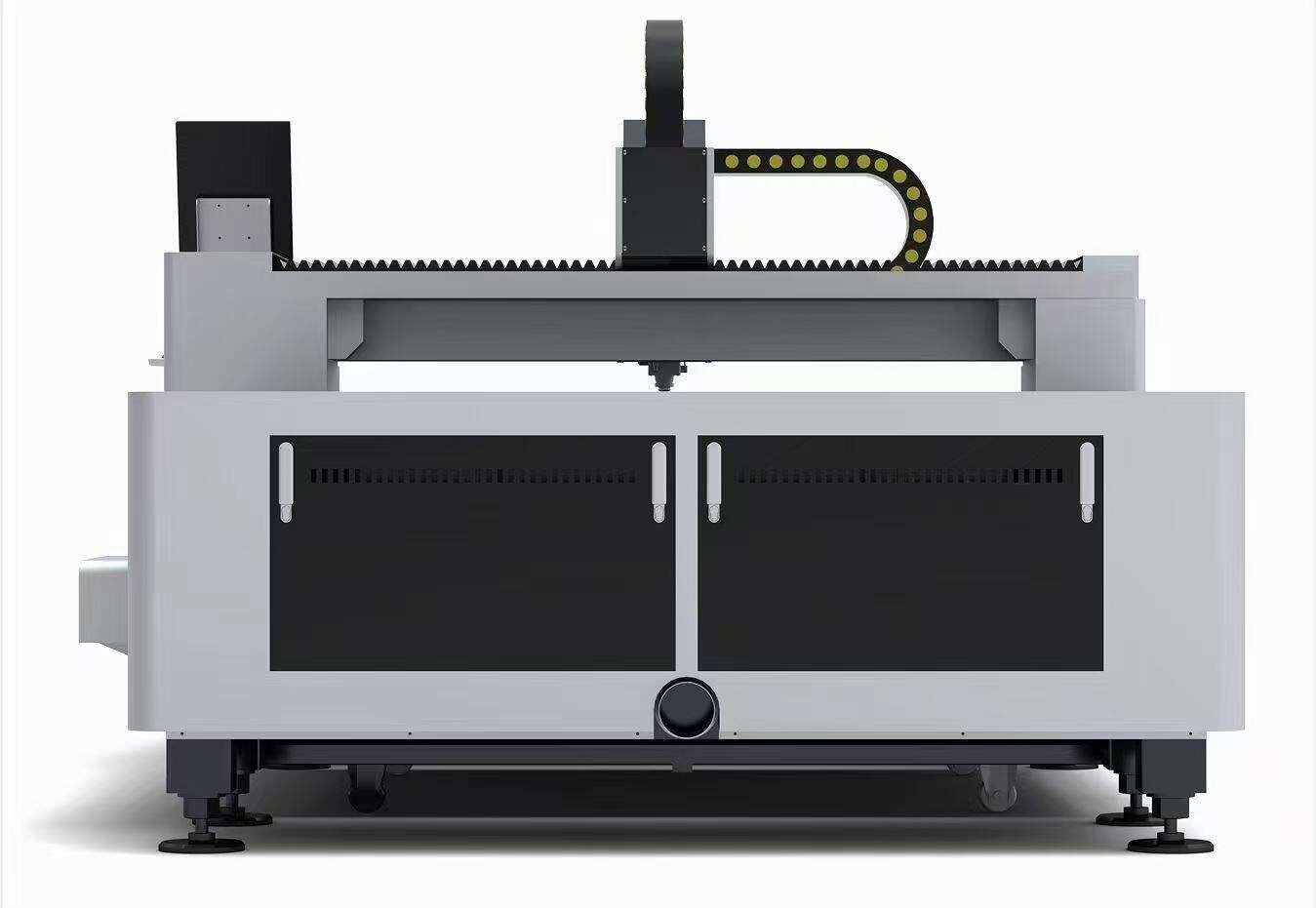

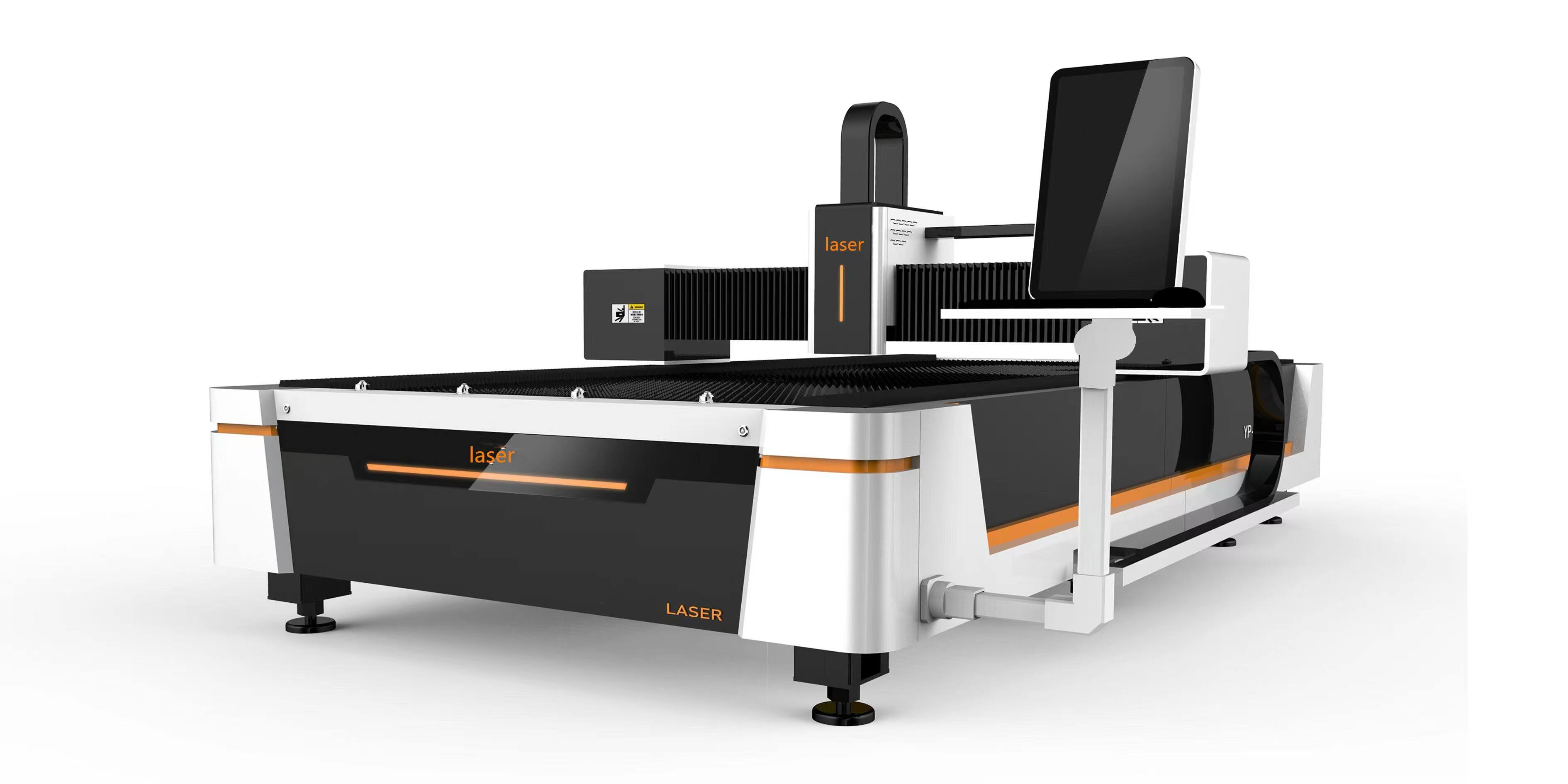

Laser cutting machines outperform other fabrication tools for various reasons. They not only have higher speed and precision over mechanical cutting, but they can also outperform bending and welding tools in complex shaping tasks along with slower deformation. In this regard, laser cutting machines are easier to use, aside from being more precise – making them a vital asset for manufacturing in today’s era