Cost - effectiveness and Simplicity

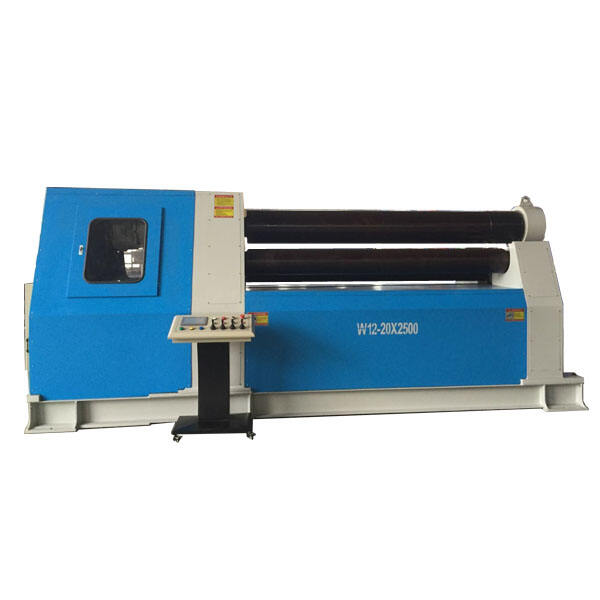

Three roll mechanical plate benders are economical due to the relatively low cost of production, maintenance, and repairs. Because they are easy to use, even small scale metalworking firms or hobbyists can utilize them. With such a mechanical structure, there are also fewer parts that can fail.